roughing end mill depth of cut

Shop Our Huge Selection of Fine Machinery. ROUGHING END MILLS Roughing cuts are generally for preparing the surface.

Ad Over 30 Years Of Quality Industrial Machinery Equipment.

. It cannot provide good surface finish and close tolerance. Roughing end mills also known as hog mills are used to quickly remove large amounts of material during heavier operations. Order Your Industrial Tools At Grizzly.

1397000 mm L. After rough cut a finish cut or finishing pass is carried out to improve surface finish dimensional accuracy and tolerance level. Read customer reviews find best sellers.

Due to variable spacing of flutes combined with the NR roughing profile vibrations cutting forces are minimized and metal removal rates are maximized. COBALT ROUGHING END MILL. Carbide Square End Mills.

762000 mm AP1MAX 1st Maximum Cutting Depth. Made of solid carbide these end mills are harder stronger and more wear resistant than high-speed steel and cobalt steel for the longest life and best finish on hard material. For high-speed roughing width of cut is usually set at somewhere between 5 and 10 percent of the cutting tool diameter.

Find deals on downcut endmill on Amazon. Climb cut is recommended for side milling. Their extreme hardness means they are brittle so a highly rigid setup such as a CNC machine is necessary to prevent the end mill from.

I think the cut length was 6. Lot 5 new cobalt 34 roughing end mills m42 milling rougher machinist tools. PREMIUM COBALT MILL SPEED FEED Multi-Flute - Side Cutting - Roughing - HSS-C08 End Mills CHARTS Aluminum Aluminum Alloys Material Hardness Diameter 14 516 38 12 58 1116 78 1-18 1-14 1-38 1-34 Carbon Steels Alloy Steels Tool Steels Carbon Steels Alloy Steels Tool Steels.

This means a 050-inch end mill will be engaged 0025 to 0050 inch. Factory small end chamfer. Factory small end chamfer.

Mm Aluminum alloy A7075 Cast aluminium AC4B. Ad Quality machines tooling spare parts and accessories for bench top machinists. The image is showing.

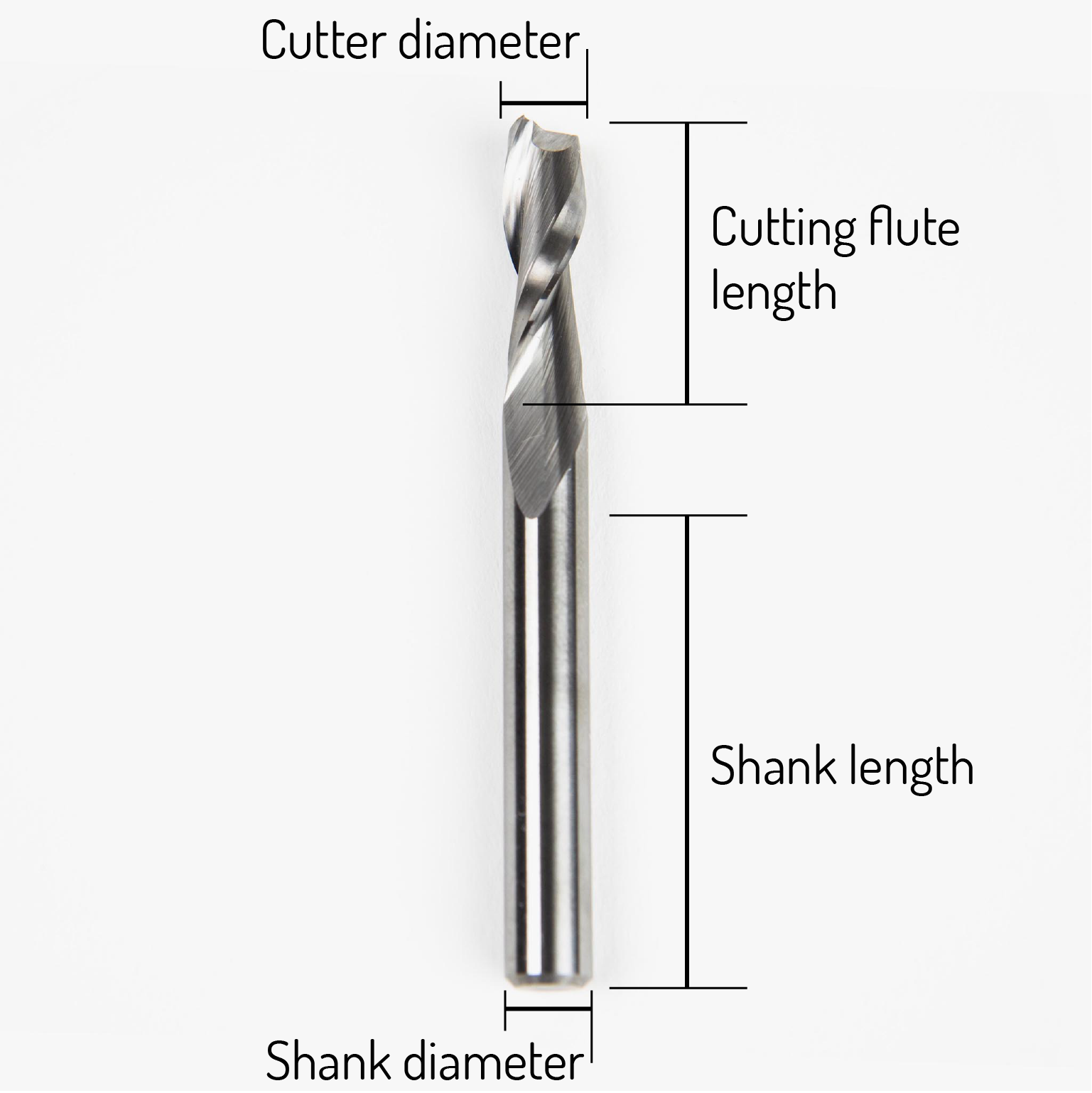

AP1MAX 1st Maximum Cutting Depth. Vibration dampening variable flute spacing. Length of cut1-58 loc.

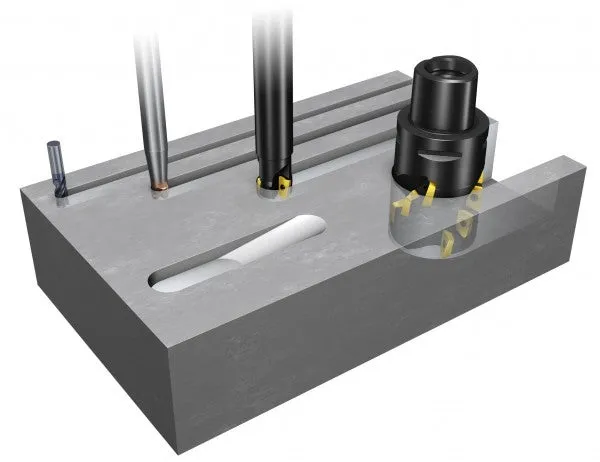

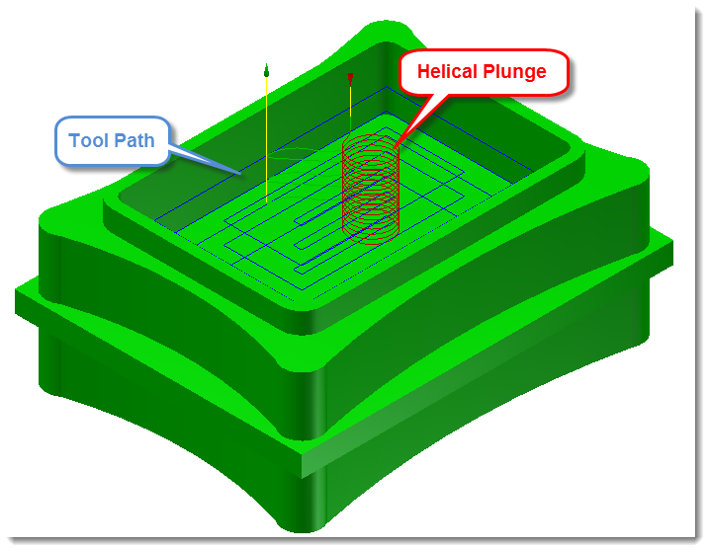

Cutting tool utilization and metal removal can be maximized by fully engaging the solid carbide end mill. Multi-Cut end mills are specifically designed for high-performance roughing operations. This step is called rough cut or roughing pass.

One problem with not taking the full 15 depth is that you wear out the end of the flutes before the rest of the cutter is done. Depending on what type of cutter you happen to utilize for the particular operation depth of cuts will vary on your CNC router. Higher feed rate and depth of cut are employed for this step so that high stock removal rate is obtained.

Ad Browse discover thousands of brands. ANSI Catalog Number. A face mill compared to roughing end mill is going to have a different material removal rate per the given operation.

3000 in L Overall Length. Two flute end mills are center cutting where multi-flute end mills can vary. Roughing end mill Short cut length 3 flute For aluminium alloy Corner radius roughing end mill Short cut length 3 flute For aluminium alloy.

Depth of Cut Maximum APMX 78 Tool Type Roughing. Multi-flute end mills create better surface finishes due to a lighter chipload - per flute. 45 high helix flute design.

A face mill obviously will have much less depth of cut compared to a smaller. Stabilizing cutting edge geometry. Depth of cut Revolution min-1 Feed rate mmmin Revolution min-1 Feed rate mmmin Dia.

Up to 16 cash back Ball end mills also known as ball nose end mills are used for milling contoured surfaces slotting and pocketing. Side loading is dramatically reduced with lower helix angles making it easier to mill thin walls. M-42 Cobalt - Fine Tooth Roughing End Mills For high production milling in difficult to machine materials such as iconel hastalloy titanium alloys and other materials up to 40 Rc.

A ball end mill is constructed of a round cutting edge and used in the machining of dies and molds. Order At Grizzly Now. Id go full depth.

HARVI III Aero Solid Carbide End Mill for High Feed Roughing and Finishing with Maximum Metal Removal Rates. Anything carbide we had was too short or ran too rough. Its typical for depth of cut to be set at 2.

Length of cut1-58 loc. Ad Contact Us For Summit Machine Tools Online Request A Custom Quote Today. Standard depths of cuts for roughing end mills can be set at a larger value than ordinary type end mills.

Years ago I had to use long 15 diameter roughing HSS mills on a weldment. Also for the same reason the depth of cut for semi-finishing end mills can be increased. This is because the cutting resistance is reduced because the chips are broken into short lengths by the wavy cutting edges.

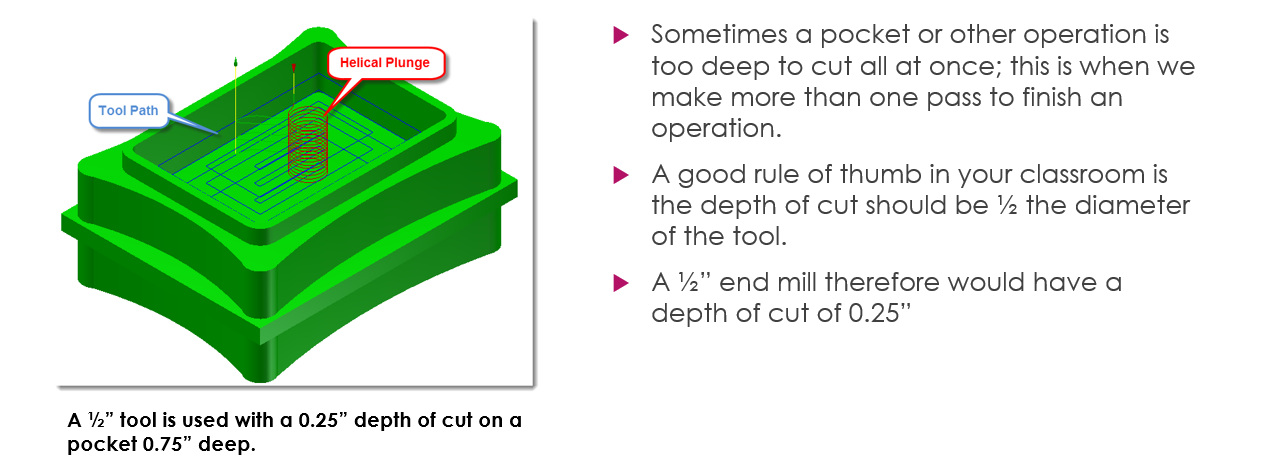

What Is Depth Of Cut How Deep Can I Cut On A Single Pass Chris And Jim Cim

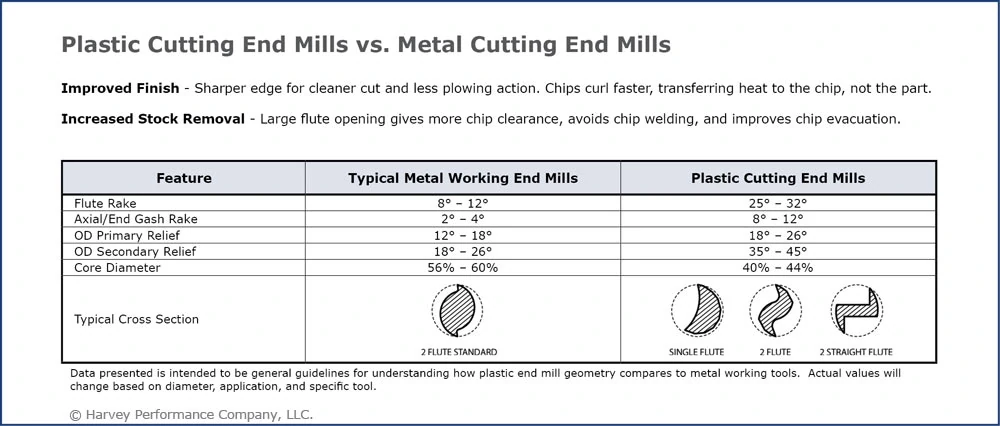

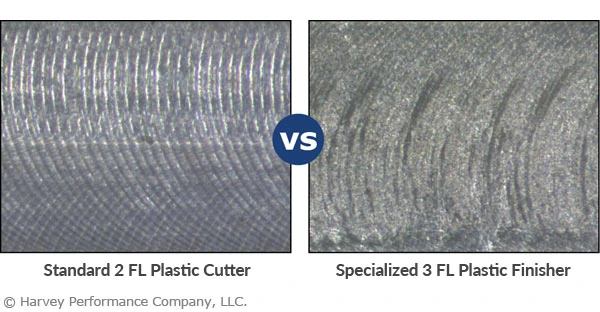

Selecting The Right Plastic Cutting End Mill In The Loupe

G76 Screw Thread On A Cnc Lathe Using G Code

Selecting The Right Plastic Cutting End Mill In The Loupe

Alimaster Mitsubishi Materials Corporation

What Is Depth Of Cut How Deep Can I Cut On A Single Pass Chris And Jim Cim

Increasing Material Removal Rates Rate Material Turn Ons

Selecting The Right Plastic Cutting End Mill In The Loupe